WATER UTILITIES USE AMI TO JUMPSTART SMART INFRASTRUCTURE SOLUTIONS

Just like smart metering made billing more efficient, smart infrastructure solutions (SIS) that incorporate sensors on advanced metering infrastructure (AMI) allow utilities to optimize the performance of their water distribution networks and wastewater collection systems. Data collected from these sensors can give deeper insight into the operational status of a water network with some common applications, including reduced non-revenue water losses, preventing unwanted sewage discharge, and monitoring pressures across the distribution network.

WHY SIS AND AMI?

Originally developed to automatically collect readings from meters to improve billing accuracy and efficiency, AMI systems can be used for much more. Typically, an AMI system covers the complete footprint of a utility’s operations and provides communications access throughout. By piggybacking on that communications infrastructure, SIS sensors allow utilities to see near real-time data results from the field with little to no extra communication fees, gaining additional value from infrastructure in which they have already invested. Three typical starting places for implementation of SIS at water utilities include:

1. Identifying underground leaks and non-revenue water by adding acoustic leak detection

2. Adding pressure sensors to the distribution network to help monitor system pressure and inform pump and pressure valve control

3. Defending against sewer overflows by adding smart sensors to the wastewater collection system

SIS helps water utilities expand the definition of smart water, offering greater network visibility, manageability, and actionable information for utilities and their customers.

IDENTIFY DISTRIBUTION NETWORK LEAKS

Underground leaks can go unnoticed for years, not only causing lost revenue for water pumped, treated, and not billed, but also washing away dirt and gravel under roads and buildings until a sinkhole appears and causes major infrastructure damage. By adding acoustic sensors and related analytics to identify and locate leaks in water pipes, utilities can avoid high-cost catastrophic pipe failure, extend infrastructure life-cycles, conserve water and power, and meet consumer and regulatory service expectations.

But physical acoustic sensors by themselves are only part of the solution. Without software that can weed out non-leak noise and analyze data to accurately pinpoint leak locations, utilities may have too many false positives for leaks, or worse, false negatives that miss leaks altogether. The right software solution combined with the acoustic sensors will eliminate the noise and electrical interference that renders some leak-detection solutions ineffective.

Key factors when considering acoustic leak detection are:

• Low maintenance automatic collection systems that don’t require constant field work

• Application software that correlates data and provides visual identification of high probability leak locations

• Diagnostics software that ensures the system is operating at peak performance and notifies operators when problems arise

• Time synchronization of collected data and sound recordings to provide automatic system-wide correlation every day

OPTIMIZE THE DISTRIBUTION SYSTEM

Pressure sensors located in the water distribution network can both guide pressure management decisions and identify anomalies that could indicate leaks. Monitoring sensors with a fixed AMI network increases their effectiveness and efficiency in making pressure adjustments in near real-time.

Data from pressure monitoring is especially useful in district metering areas to:

• Perform flow and pressure calculations to show leaks

• Compute water balance and determine minimum night flow

• Identify where pressure can be lowered to reduce leaks and energy used to pump

• Control district metering area (DMA) gate valves

Pressure monitoring on an AMI network can help utilities reduce wear and tear on pipes, minimize water volume lost to actual leaks, and lower the chances of burst pipes by allowing operators to quickly reduce pressure when necessary. It is also useful in helping operators monitor pressure to maintain minimum service pressures as well as determine where problems exist when they receive low-pressure complaints. Pressure monitoring can also provide data necessary to calibrate hydraulic models.

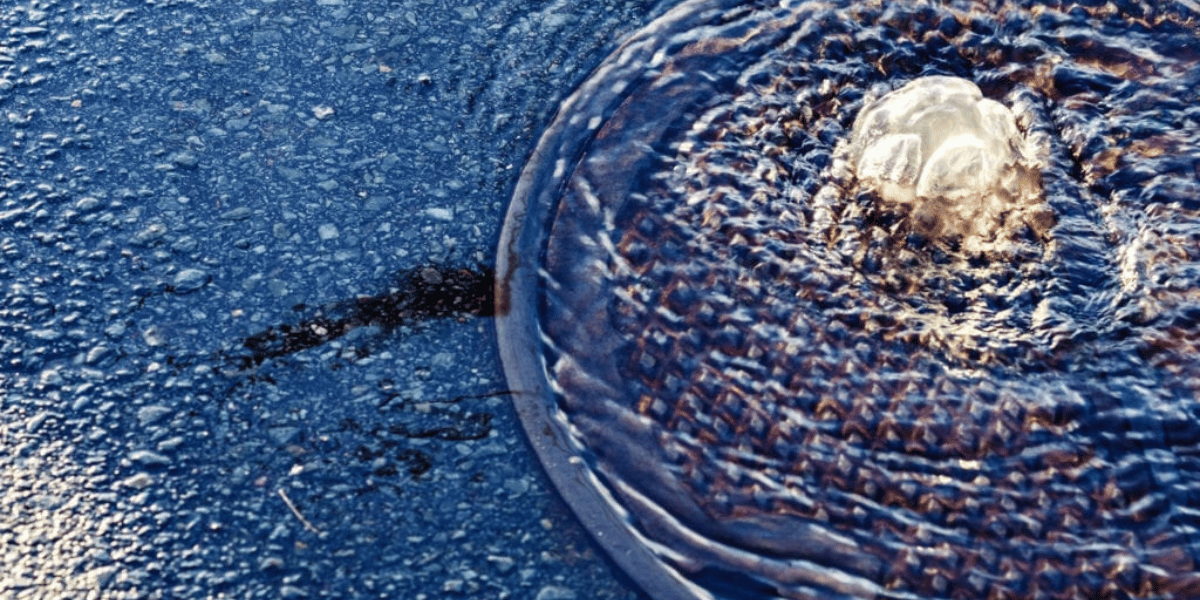

PREVENT SEWER OVERFLOWS

Preventing sanitary and combined sewer overflows (SSOs and CSOs), which may discharge raw sewage into the environment, is a national enforcement priority for the Environmental Protection Agency (EPA) in the United States. An estimated 40,000 overflows each year are caused by events such as pipe blockage, severe weather, vandalism, and improper system operation and maintenance.

As a result of this government focus, water and wastewater utilities are looking at a variety of technologies to prevent overflows. One is the use of sensors to determine when water and sewage levels are rising in sewers or when manhole tampering has occurred.

These sensors, when operating on a fixed network, reliably provide near real-time monitoring of manholes and other key sewer locations. Whether used for early warning of overflows, informing maintenance schedules, satisfying compliance reporting requirements, or providing deeper analytics (such as capacity modeling and performance reporting), sewer monitoring is a crucial solution for managing sewer overflows.

———-

*Dave Rubin is Director of Product Management with Aclara and leads the Water AMI Team. To learn more, visit aclara.co

Comments